muscle memory

Muscle memory.

Zeitgeber.

We live surrounded by material rhythms, some we survive, and some survive us. Humans occupy a time frame limited by their life cycle scope. A human is born into an environment, learns, coexists, maybe contributes and then dies. Waves of material and immaterial dynamics precede us like tectonic plates, which constantly shift at a glacial pace or the relentless lapping of the oceans, and still will be there when we disappear. Some of the man-made systems that we created like industrial infrastructures, byproducts or waste, will survive our existence as a new landscape, maybe inert or generating other ecosystems and landscapes themselves.

The circadian rhythm is the approximate 24 hours cycle marked by our days and nights and it’s also built in plants, animals or bacteria. The term «zeitgeber» (German for «time giver» or «synchronizer») was first used by Jürgen Aschoff, one of the founders of the field of chronobiology. This cycle helps us understand how we exist in the world according to certain (sometimes unconscious) rhythms and how we impose those rhythms to other beings and procedures. In a way, how we are programed and we program other structures according to already existing ones. How we interpret water as a sign of possible life in other planets is just because we only understand life through water. The paradigm of life on earth shapes how we understand life itself, and conditions us to image other possible realities.

Collective knowledge, science and research are constructed by humans but still conditioned by the life cycle of every individual taking part of his society. Scientific progress is subject to the vital limits of the scientists life cycle and will be continued and reformated, or not, by the following generations, restricted as well by their own life limitations. This generates a chain of gains and losses of information, recording, carrying, translating, and interpreting information as a specific community cycle. Same as it happens in our skin, contributors to the system, cells are born and others die but the skin continues to operate as an organ, influenced by exterior and interior changes.

We share space-time with other artificial cycles created by us like a pure bred dog, a genetic modification, or we should say commodification, of an existing species to match our functional or esthetic desires. Or a Tamagochi™, a Japanese origin handheld digital pet in the shape of an egg that one could tickle, feed or starve to death. Both living timelines, products, one organic, the other electronic, that we breed and take care of, mostly because our average time line exceeds the duration of theirs. Parallel cycles, other narrations that succeed because we survive them while satisfying the caring and breeding we are programed for.

Tendon.

A bone and a muscle have different densities and functions, both perfectly designed by evolution towards a purpose. A tendon is an interface between those two, a passive and an active element. The figure of the tendon is crucial for the positive thinking of our intervention in the territory we inhabit. We humans prioritize on the effectiveness, the immediateness and the profitability of processes. We tend to relativize the figure of the tendon, the transitional element that allows the system to operate.

In the post-industrial era all the new constructions, inventions and structures we humans have imposed into our environment are a reflex or reaction to existing ones. As the recurring myth of Prometheus, name it Frankenstein, Blade Runner, Terminator or Her, human narratives depict the fixation to the idea of his creation surpassing, dematerializing or even extinguishing them. This is one reason why the notion of equilibrium and pertinence are so crucial in the anthropic-organic relation. On the way we humans have developed our world over industry and resources, this not only means a direct extraction of a material like oil or coltan, but by observing and mimicking nature’s solutions and applying them to serve our interests. Nature’s evolutionary engineering, as a bag of inspiration for human challenges and aspirations is usually unconscious and detached from the source and its balance.

Metal foam.

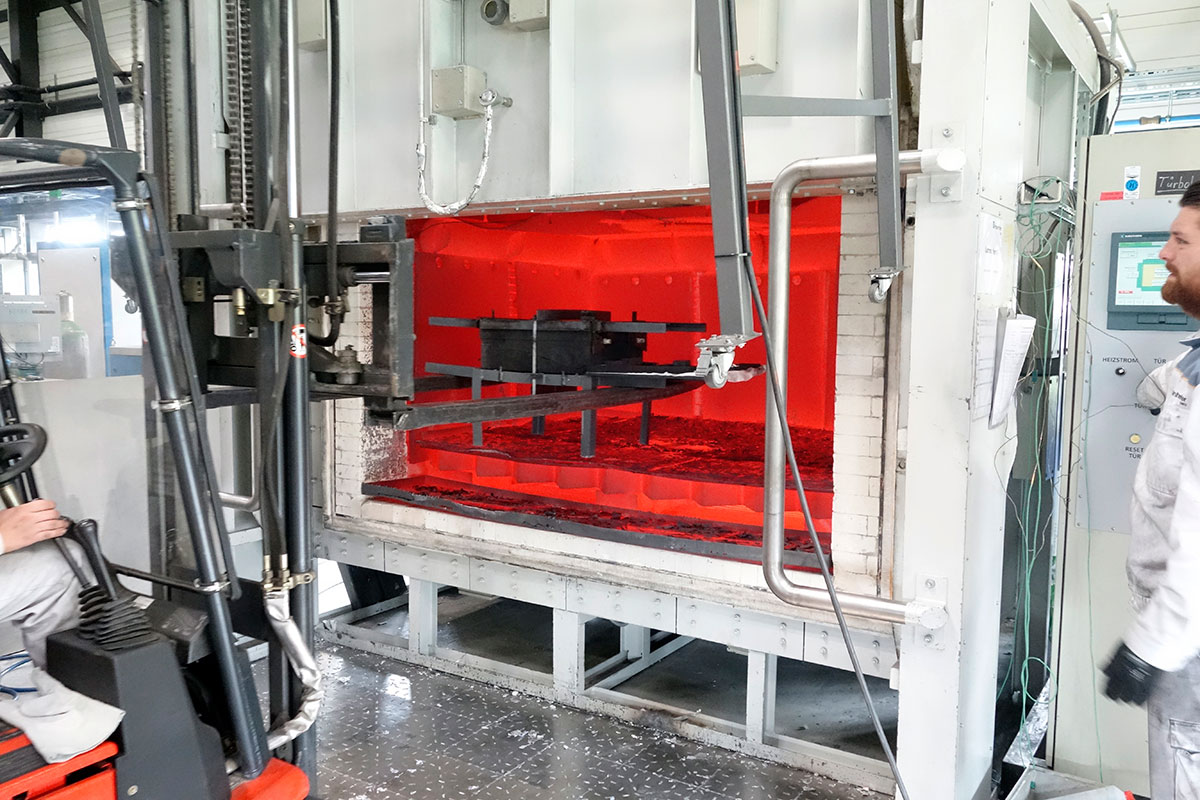

In 2014 in a material research lab, I tumbled with a piece of metal foam, strong as aluminum but 10 times lighter. An extremely porous piece of metal where 75-90% is just empty and consists on bubble shaped spaces, surrounded by a thin aluminum crust. The bubbles are produced by the expansion of an inert gas inside a precursor material when heated over 250º.

The standard commercialized appearance of this material is a very perfect orthogonal sheet filled by this chaotic and rather irregular foam inside, but it can also be turned into any shape using a graphite mold. Some kind of contradiction between organic and industrial as it happens in its name. Both words, metal and foam, seem antagonistic from a material point of view. One is a transitory state, which alludes to inconsistency, and the other a mineral solid state with connotations of persistence and endurance. The paradox embodied in that material alludes the use of organic phenomena, like the foam we observe in soap or sea waves, as a direct resource. So in the same way we prospect a mineral, here we replicate a phenomena, a change of state into profit.

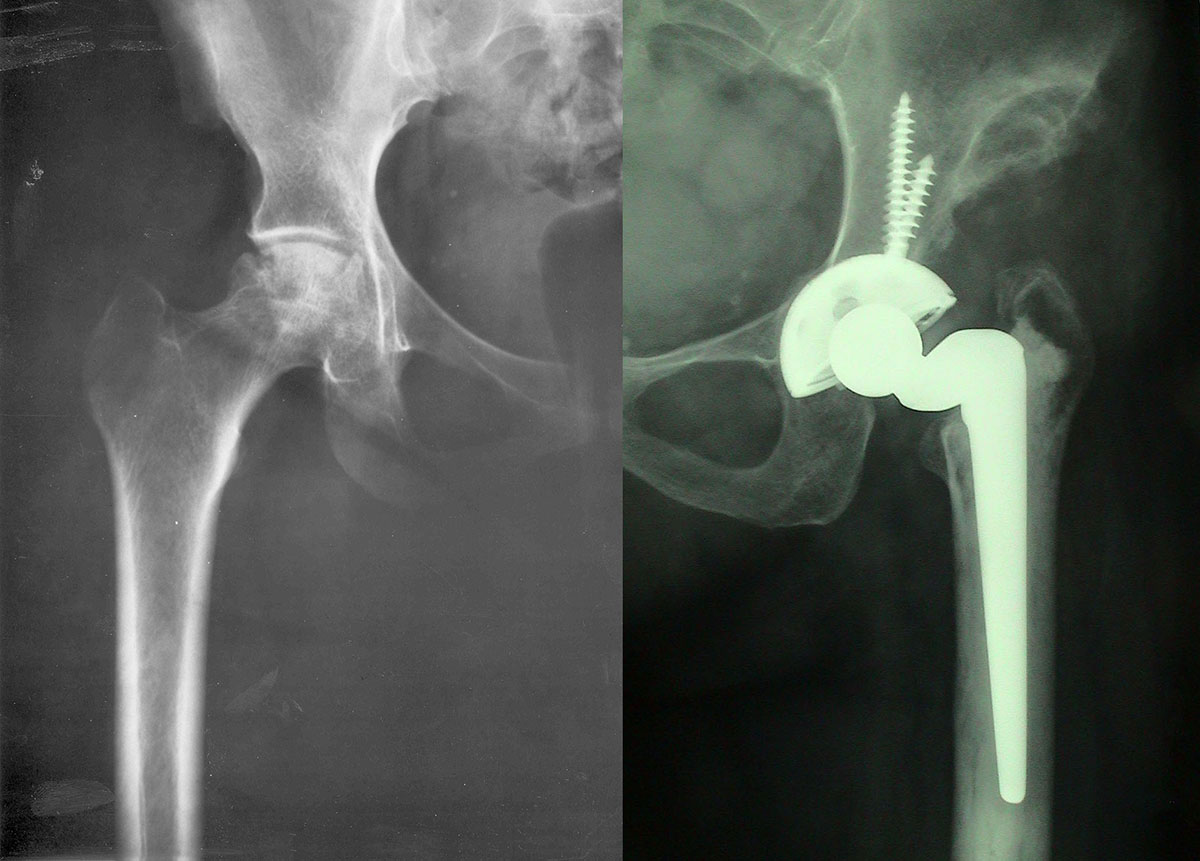

Many direct researches pointed to the same person as the guru in the subject Dr. John Banhart whom I visited at the Freie Universität in Berlin. I was triggered when he mentioned that the first application of this material was meant to be in human prosthesis, and how tough, almost impossible it had been to raise funding for this purpose. Metal foam, a material with a composition similar to bone structure: light, cavernous interior and covered by a strong skin. The medical field sought to apply the new material to bettering the quality of human life, but the much more dynamic and most lucrative market around the automotive industry assimilated and adapted the highly sophisticated technology of metal foam much faster. These companies represent the vector of economical progress more focused on generating desire than bettering human conditions, representing the otherness, and materializing the externalization of the self. So it happens that the timing for prosthetic validation takes much longer than the same material to be assumed and digested by, say, the aerospace or the luxury car industry. So today, while medical engineering was the aim in first place for its developers, we have this material in Ferraris and satellites around the earth but still didn’t make it into the bettering of the human body.

The fascination for smaller cycles than human time scope appears here again, paralleling tempos in relation to the industrial and post-industrial structures as a reflex of human behavior. On one side how we emulate nature and natures phenomena into productive purpose, and how the industrial structure is also some kind of organism manifesting his own pace and hunger in processing times.

After contacting, visiting and meeting with different companies in the sector (like Pohlthec wich was crucial in the process), I was advised to approach the Fraunhofer Institute, a German institution dedicated to researching and developing technical solutions for many industrial fields and specifically their facilities in Chemnitz are pioneers on the development of metal foam.

My intention was not to use metal foam as a material for a piece of sculpture, but to intervene in the process of how this industry is fed and digests new phenomena into a product. Considering here the whole industrial time line dedicated to the development of a new material just as a giant digestive system. Metaphorically speaking, starting from research areas, where university students could be the saliva and public funding the vitamins. Where University labs perform as the first cavities like mouth and esophagus meant to set up this material for further process. Then the research centers equally funded by the acid juices of public and private resuorces could be the stomach where decisions are taken to satisfy the professional fields. The raw matter is taken apart by the enzymes for further digestive selection. Almost at the end of that process, the nutrients are extracted just like techniques and resources are ready to suit the market. The enzymes and bacteria in the intestine distill the essential elements already driven by a demand of this protein or that glucose… There’s room here for the reader to imagine about waste’s configuration.

Catalyst.

After long discussion, and of course not mentioning a word about the crazy digestive theory that, with all justice, would’ve got me kicked out of there immediately, Fraunhofer Institute agreed to let me access a prototype mold for a motorbike tail. A brand we cannot mention had funded the research for that piece and they developed one of the first prototypes which didn’t progress into production. The graphite mold used for this process costs 30.000€ and its an industrial secret, so the conditions are: I cannot name the company and I can use the mold but afterwards it has to be destroyed or made unusable. Those are the sacrifices of working in between the cracks of technology research, so I turned those conditions into an imaginary mold to make the productive engine even more transparent.

The intervention I applied in the Fraunhofer Institute tries to revert that estrangement that happened in the history of this material, in the continuation of that digestion metaphor stated before, more of an industrial trough up. I first learned how to fill the mold and get it operative and reproducing the perfect pieces. Pressure and temperature are the two conditions that shape the piece inside the mold. So once the “production line” was warm and running, there was a flow of pieces. Then I applied two small holes in two edges of the mold. Once opened in the graphite there’s no way back and the bigger they become the less effective the pressure inside the mold. So in each new “baking” the mold was becoming less powerful, and the industrial pressure applied to the material inside was diminished. A deflation of the industrial apparatus happened in a sequence, until the last piece performed a shrunk and collapsed piece, an organic shape piece that shows more of its vulnerable precedent foam phenomena, unable to perform, to play any role in the industrial competition. Fragile, no aerodynamics, no stress test please.

A new material inducts a reaction within the industrial organism, acting as a catalyst. A metabolism based on profits synthesizes material applications in the same way a body processes sugar, or protein. The industrial organism does not distinguish between social stratifications.

Carlos Irijalba, Amsterdam 2017

Metal foam lab production shot: Fraunhofer-Institute Chemnitz (DE)

Metal foam lab production shot: Fraunhofer-Institute Chemnitz (DE)

Installation shot: Schloss Ringenberg (DE)

Deflated motorbike tail: (variable dimensions)

Detail

Detail

Detail

Deflated motorbike tail: (variable dimensions)

Graphite mold deflation: (detail)

Hip titanium prosthesis

Metal foam motorbike tail section

Floating metal foam installation